An acrylic stand is a versatile display and organizational accessory made from transparent or colored acrylic (polymethyl methacrylate). Thanks to its clarity, durability, and ease of fabrication, acrylic stands have become ubiquitous in retail, offices, exhibitions, and home décor. This article explores what acrylic stands are, how they’re acrylic stand, the myriad ways they can be used, and best practices for designing, choosing, and maintaining them.

1. What Is an Acrylic Stand?

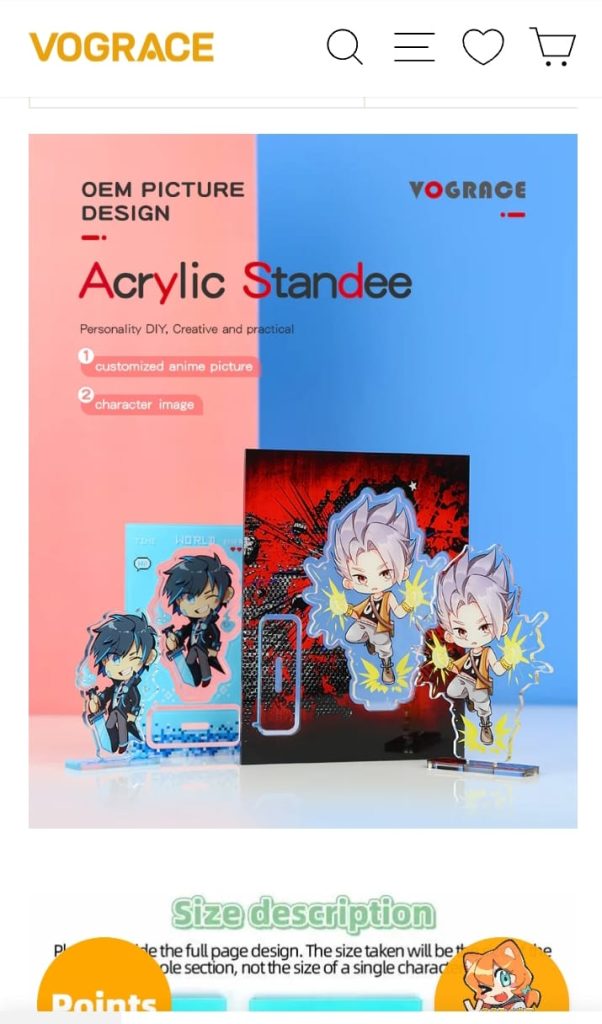

An acrylic stand is essentially a three-dimensional structure—ranging from simple L-shaped bookends to complex multi-tiered display risers—fabricated from sheets of acrylic plastic. Acrylic offers a glass-like acrylic standee(up to 92% light transmission), is shatter-resistant, and can be cut, bent, polished, or printed with high precision. These attributes make it ideal for showcasing products, organizing literature, or providing a sleek, modern aesthetic.

Key properties of acrylic:

- Transparency: Almost as clear as glass, enhancing visibility of displayed items.

- Lightweight: Approximately half the weight of glass, easing installation and shipping.

- Durability: Highly impact-resistant; less prone to cracking or shattering.

- Workability: Can be laser-cut, CNC-machined, thermoformed, or hand-polished.

- Weather resistance: Stable under UV exposure and humidity when properly treated.

2. Common Types and Designs

Acrylic stands come in an enormous variety of shapes and configurations. Some popular categories include:

- Retail Display Stands

- Single-tier or multi-tier risers for cosmetics, electronics, or jewelry.

- Slanted brochure holders or literature racks.

- Point-of-Sale (POS) Sign Holders

- Freestanding menu displays, table tents, or menu boards.

- Acrylic Shelving and Bookends

- Floating shelves, desktop organizers, or book support wedges.

- Photo and Art Frames

- Two-panel sandwich frames with magnetic or screw fixtures.

- Trophies, Awards, and Nameplates

- Engraved blocks, plaques, or geometric shapes for special recognition.

- Product Prototypes and Samples

- Transparent mock-ups for architecture, engineering, or product design.

Each design can be fine-tuned in terms of sheet thickness (commonly 2–10 mm), color tint (clear, frosted, or solid hues), edge finish (polished, flame-finished, or raw), and custom printing (UV printing or vinyl decals).

3. Manufacturing Processes

Acrylic stand fabrication typically involves:

- Sheet Cutting

- Laser Cutting: High precision, smooth edges; ideal for intricate shapes.

- CNC Routing: Good for thicker sheets; robust for volume production.

- Thermoforming / Bending

- Sheets are heated to glass transition and bent around molds to form 90° or curved angles.

- Bonding and Assembly

- Solvent Welding: Uses monomer solvents to fuse edges invisibly.

- Adhesive Bonding: Two-part acrylic glues or UV-curing adhesives for colored and specialty applications.

- Finishing

- Polishing: Flame or mechanical buffing to achieve optical clarity on edges.

- Printing and Decoration: UV flatbed printing, pad printing, or attached vinyl graphics.

Factors such as joint strength, edge clarity, and surface hardness must be controlled to produce professional, scratch-resistant stands.

4. Applications and Benefits

4.1 Retail and Exhibition

- Product Visibility: Clear acrylic doesn’t distract from the merchandise, allowing products to “float.”

- Modularity: Interlocking or stackable units let retailers adapt displays quickly.

- Professional Appeal: Polished acrylic lends a premium look to cosmetics, watches, or luxury items.

4.2 Office and Home Organization

- Desk Accessories: Pen holders, file trays, phone charging docks, and business card stands.

- Literature Displays: Brochure holders, magazine racks, and leaflet dispensers in reception areas.

4.3 Events, Awards, and Gifts

- Custom Awards: Engraved shapes or embedded inclusions for corporate milestones or sports trophies.

- Memorial Displays: Photo frames, keepsake boxes, and shadow-box stands.

4.4 Artistic and Architectural Models

- Transparent Models: Allow viewers to peer through layers, making acrylic ideal for cross-sectional prototypes.

- Lighting Integration: Edge-lit stands can serve as illuminated signage or decorative art pieces.

5. Choosing the Right Acrylic Stand

When selecting—or specifying—a bespoke acrylic stand, consider:

- Purpose and Load Capacity

- Lighter brochure holders need thinner acrylic; heavy electronics require thicker, reinforced panels.

- Visibility Requirements

- Ultra-clear (optical grade) vs. standard clear. Frosted or colored for branding contrast.

- Assembly and Portability

- Knock-down kits vs. permanent solvent-welded fixtures.

- Environmental Factors

- UV-stabilized sheets for outdoor signage; anti-scratch coatings for high-traffic areas.

- Budget and Volume

- Laser‐cut one-offs are costlier per piece; high‐volume orders justify custom tooling.

Engage with a reputable acrylic fabricator who can provide material certifications (e.g., UV resistance, flame retardancy) and prototype samples.

6. Maintenance and Care

Acrylic, while durable, can scratch easily and attract dust. To extend the life and clarity of your stand:

- Cleaning: Use a soft, lint-free microfiber cloth with mild soap and water. Avoid ammonia-based cleaners (e.g., glass cleaner) which cause crazing.

- Scratch Removal: Light scratches can often be buffed out with a plastic polish compound and a soft buffing pad.

- UV Protection: If outdoors, periodically inspect for yellowing; replace stands after extensive sun exposure if clarity degrades.

- Handling: Always lift from the base or reinforced edges—don’t drag across rough surfaces.

7. Customization Trends

The market for acrylic stands has evolved beyond plain “clear” into creative and branded solutions:

- Gradient and Two-Tone Acrylics: Laser etching combined with colored layers for dynamic visual effects.

- Embedded LEDs: Edge-lit stands that illuminate logos or product silhouettes.

- Modular Shelving Systems: Snap‐together interlocking components for scalable retail fixtures.

- Eco-Friendly Alternatives: Recycled acrylic sheets or bio-based polymers that reduce carbon footprint.

Such innovations help brands stand out and create memorable point-of‐sale experiences.

8. Conclusion

Acrylic stands marry form and function in countless environments—from showcasing high-end jewelry to organizing office supplies. Their transparency, durability, and flexibility in design make them a go-to for anyone looking to elevate product presentation or streamline organization. By understanding fabrication methods, choosing the right material specifications, and practicing proper maintenance, you can maximize both the aesthetic impact and longevity of your acrylic stands. Whether you’re a retailer, event planner, designer, or DIY enthusiast, acrylic stands offer a modern, polished solution to nearly any display or organizational challenge.

5/5

o4-mini